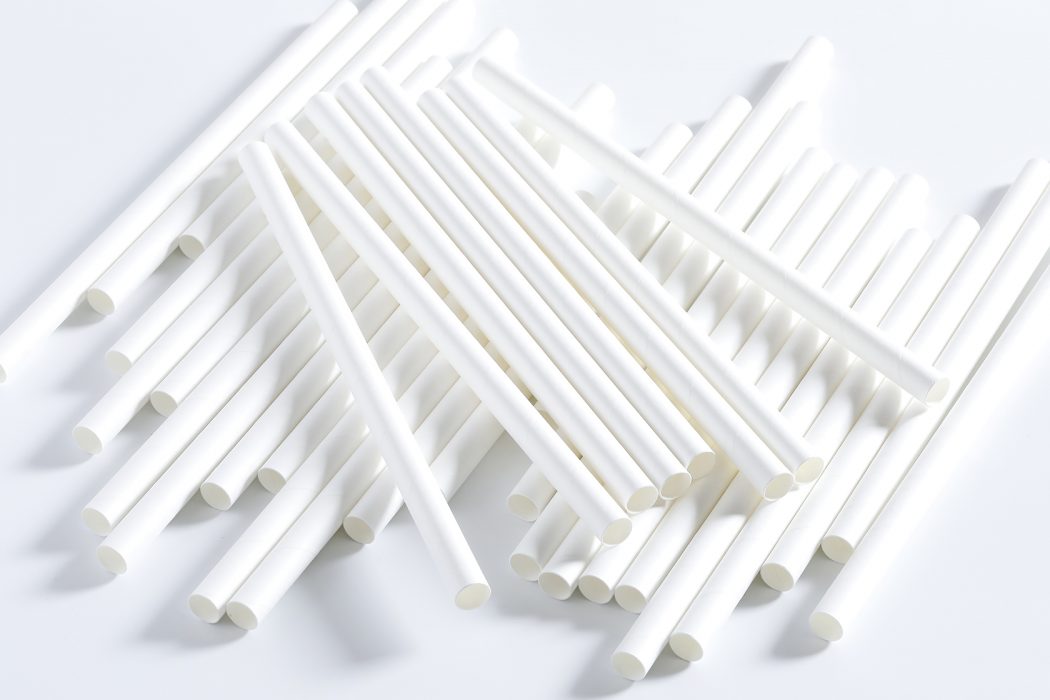

Who We Are

Established in 1986 as an SME specializing in the production of paper tubes for chemical fibers, our products include a wide variety of paper tubes for use in the textile industry, for industrial use, and also for packing. Taiwan SUGONG brand was established in 2017, is the first paper tube manufacturer to expand the production of food-grade paper straws in taiwan.

The straw shouldn’t be in the ocean or any organism. Regardless of the straw made of any material, the most important thing is that it can be recycled properly after use.

SUGONG hopes to use eco-friendly paper straws as the original intention, and hopes that the public can be more friendly to the global biological environment without losing its convenience.

The details of making a paper straw are far more difficult than imagined!

The choice of raw materials is the key. SUGONG uses food-grade non-coated virgin pulp and synthetic resin to make paper straws. Safe ingredients allow users to drink with peace of mind.

The first step: roll tube system

- Raw paper slitting machine— Divide the paper raw materials into the appropriate size of the required width of the paper straw (10mm-50mm).

- Winding machine— Wind the paper tube into three layers of paper strips, the upper, middle, and lower winding angles are calculated to ensure that the paper straws are firm and do not fall apart, and can be rolled into various sizes (φ4mm – φ25mm).

- Fine-cutting machine— Cutting the paper tube according to the required length (5mmL-1200mmL).

The second step: drying semifinished

- In order to make the paper straws more durable, the semi-finished product formed and cut from the roll tube will be sent to the drying conveyor to remove the water from the paper tube and let the adhesive exert its characteristics. When the adhesive is fully matured, it will adhere to the paper more closely. This step prolongs the life of the product and is sterilized by the UV shutter.

The third step: diagonal cut processing

- In addition to ensuring the selection of raw materials and enhancing the toughness and durability of the process, SUGONG has made sufficient preparations for the diagonal cut processing. We actuated the cutting angle of the bevel and measured the different styles of sealing films of various merchants. Piercing the plastic sealing films of hand-cranked beverages on the market will no longer be a problem.

The fourth step: single packaging / bare bag packaging

- According to customer needs, our finished products are divided into single paper sleeve packaging and multiple bare bag packaging. The order requirements are completed according to the order content, packaging, boxing, sealing, and shipping!